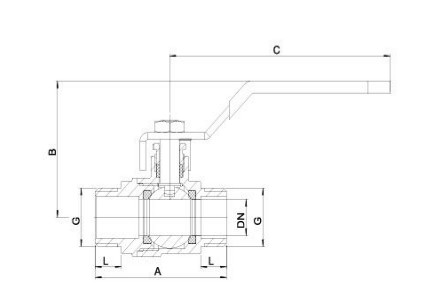

| G | DN | A | B | C | L |

| 1/2" | 13.5 | 52.5 | 50.5 | 96 | 12 |

| 3/4" | 19 | 60 | 53 | 96 | 12 |

| 1" | 24 | 75 | 60 | 118 | 13.5 |

| 1 1/4" | 29 | 82 | 69 | 118 | 15 |

| 1 1/2" | 37 | 93 | 80 | 165 | 16.5 |

| 2" | 45 | 112 | 85 | 165 | 20 |

| Light | |||||

| G | DN | A | B | C | L |

| 1/2" | 13 | 49 | 49 | 88 | 10.5 |

| 3/4" | 18.5 | 55 | 50.5 | 88 | 10.5 |

| 1" | 22 | 63 | 55 | 125 | 12.5 |

| 1 1/4" | 29 | 79 | 65 | 125 | 14.5 |

| 1 1/2” | 37 | 91.5 | 78 | 152 | 15 |

| 2" | 43.5 | 106 | 85 | 152 | 15 |

| G | DN | A | B | C | L |

| 1/2" | 13.5 | 52.5 | 40.5 | 52 | 12 |

| 3/4" | 19 | 60 | 42.5 | 52 | 12 |

| 1" | 24 | 75 | 48 | 67 | 13.5 |

| Light | |||||

| G | DN | A | B | C | L |

| 1/2" | 13 | 49 | 46 | 52 | 10.5 |

| 3/4" | 18.5 | 55 | 47.5 | 52 | 10.5 |

| 1" | 22 | 63 | 52 | 67 | 12.5 |

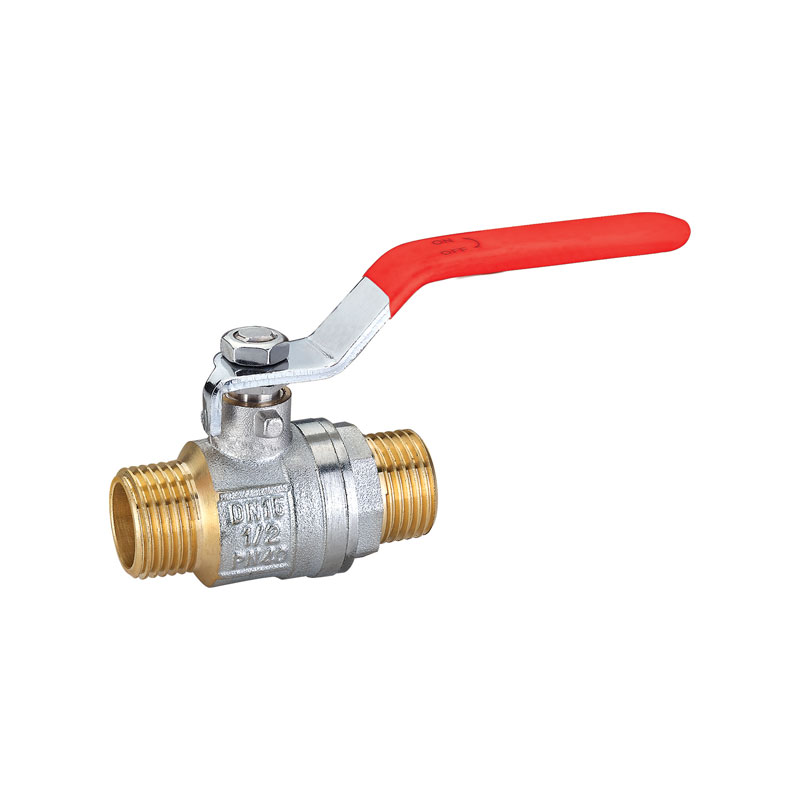

More product information about Good price long handle M/M thread brass ball valve A-2003

One of the most prominent advantages of using a long handle M/M thread brass ball valve is its exceptional durability. Brass is a robust and corrosion-resistant material, making it ideal for withstanding harsh environments and demanding conditions. This durability ensures that the valve can maintain its functionality for an extended period, reducing the need for frequent replacements and maintenance.

Brass is naturally resistant to corrosion, which is crucial when dealing with fluids that may contain corrosive elements. This resistance makes long handle brass ball valves suitable for applications in industries like chemical processing, water treatment, and oil and gas, where exposure to corrosive substances is common.

Long handle M/M thread brass ball valves are highly versatile and can be used with a wide range of fluids, including water, oil, gas, and chemicals. This versatility makes them suitable for a multitude of applications, from residential plumbing to industrial processes.

The long handle design of these valves provides a significant advantage in terms of ease of operation. The extended handle allows for effortless manual control, even in hard-to-reach or tight spaces. This simplicity of operation is especially valuable during emergencies or when quick adjustments are needed.

Brass ball valves feature a spherical ball with a hole in the middle, which can be rotated to control the flow of fluid. When the valve is fully closed, the ball seals tightly against the valve seat, preventing any leakage. This reliable sealing mechanism ensures that the valve can effectively stop the flow of fluids when necessary, reducing the risk of spills or leaks.

Long handle M/M thread brass ball valves are known for their low maintenance requirements. Their sturdy construction and corrosion-resistant properties mean they can withstand long periods without needing repairs or replacements. This not only saves time and money but also minimizes downtime in industrial settings.

Brass ball valves are designed to have a straight-through flow path when fully open, resulting in minimal pressure drop. This high flow capacity is essential in applications where maintaining fluid velocity and pressure is critical, such as in large-scale industrial processes.

Brass has excellent temperature resistance, making long handle M/M thread brass ball valves suitable for both high and low-temperature applications. Whether it's managing hot water in a heating system or handling cryogenic fluids in a scientific laboratory, these valves can maintain their functionality without warping or failing due to extreme temperatures.

Longevity is a key advantage of brass ball valves. They have a long service life, ensuring that they can endure years of continuous use without deterioration in performance. This long-term reliability translates to cost savings for businesses and peace of mind for users.

Considering their durability, versatility, and low maintenance requirements, long handle M/M thread brass ball valves offer excellent value for the price. Their initial investment is often justified by the reduced need for replacements and repairs over time, making them a cost-effective choice for various applications.

Brass is a non-sparking material, making brass ball valves suitable for environments where there may be a risk of ignition due to the presence of flammable gases or liquids. Their ability to control the flow of such substances safely is critical in industries like petrochemicals and manufacturing.